In a recent column, my friend Paul McBride, shared some important information on pre-heating an aircraft engine (Should I preheat the oil in my aircraft engine during the winter?)

There was quite a bit of discussion on the column, so I thought I would give some background on several of the recommendations.

For example, one method discussed was draining the oil and keeping it in a warm area overnight and then adding it back to the engine just prior to starting.

This was standard operating procedure for large radial engines during World War II. Many of the airfields in northern Europe and Alaska did not have pre-heating facilities, so they would drain the oil after the last flight of the day. They would mix the oil with a prescribed amount of avgas and place it in a heated area until the next flight.

It’s important to remember that this was before the introduction of Aeroshell Oil W in 1958, so all they had was straight mineral oil qualified against the Mil L 6082 specification.

In fact, that specification used to have a minimum requirement for a diluted viscosity that measured the thickness of the oil with a specified amount of avgas diluent.

Just prior to the next flight the crew would fill the crankcase with the warm diluted oil. Then they would pull the prop through to force the oil to all areas and to check against a hydro-locked cylinder. They would then fire the engine up and let it warm up. This helped to evaporate most of the fuel in the oil prior to takeoff.

This procedure could be used in an opposed engine in an emergency.

However, there is another problem with opposed engines in very cold weather.

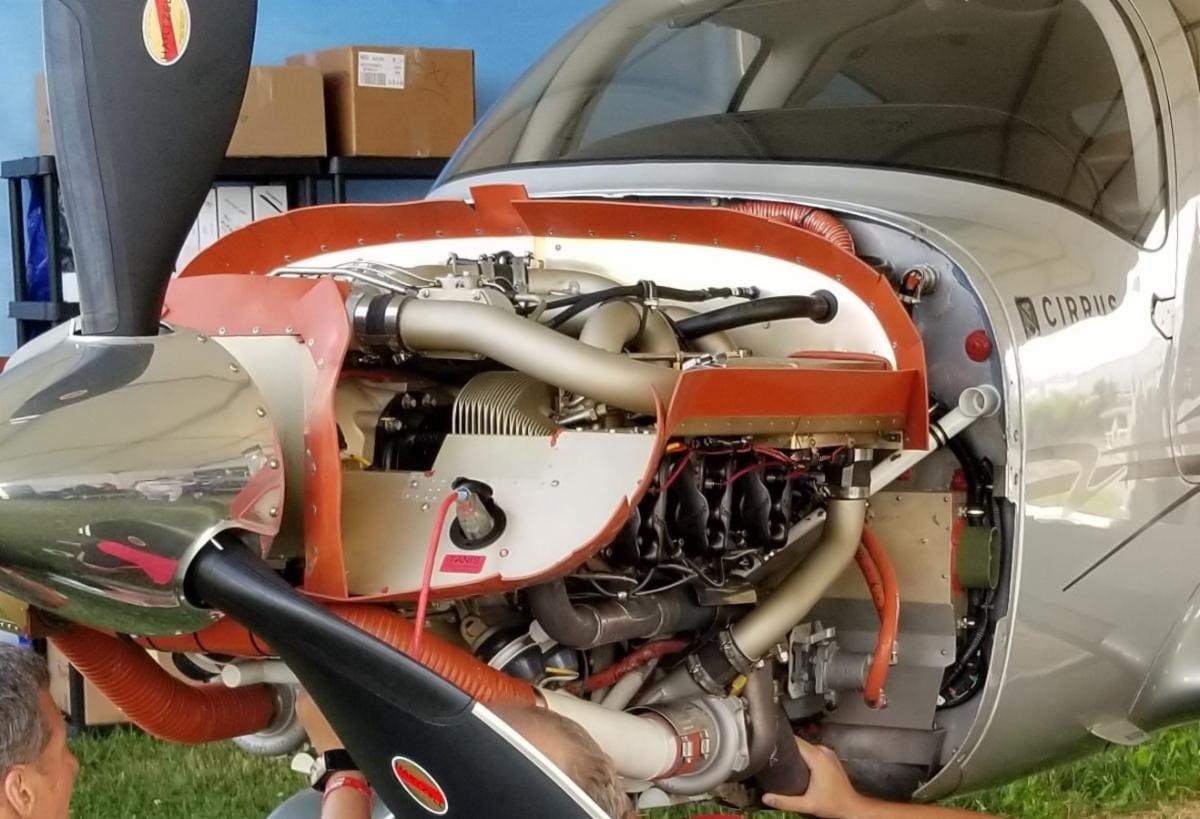

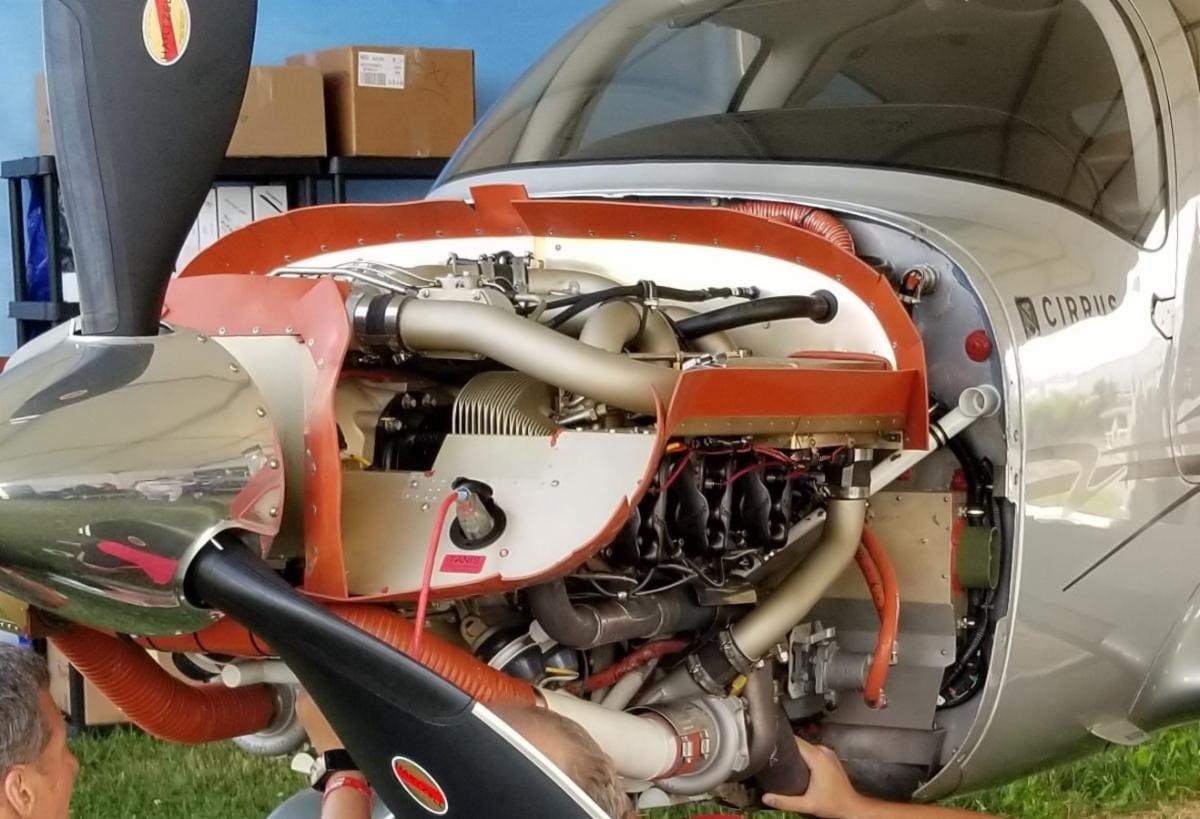

In an opposed engine, there is an aluminum crankcase that holds plane bearings against an iron crankcase. Unfortunately, the aluminum crankcase has a higher coefficient of thermal expansion than the iron crankshaft.

Since bearing clearances are set at room temperature, this means that the colder the ambient temperature, the lower the bearing clearance and the less room for the lubricant to reach the critical bearings to crankshaft interface.

The bottom line is pre-heating your engine is not just to thin out the oil, but also to normalize the clearances for the engine itself.

This brings us to the subject of electrical pre-heaters and the practice of leaving them plugged in all of the time.

Years ago, Tanis Aircraft Products developed a system for preheating an aircraft engine electrically.

The system had a small heating pad attached to the oil pan and then individual heaters for each cylinder, either in the thermal couple spot or attached to the cylinder with a steel band. This worked well because it not only heated the oil, but also the engine assembly.

Tanis then added cowl plugs and a thermal blanket to keep the entire engine assembly warm and, in some cases, they even placed a small vent fan on the oil breather to draw out the moisture.

With this system company officials claim that it is OK to plug the system in and let it operate continuously.

Unfortunately, there are several other companies that went the cheap route and just attached a larger heating pad to the bottom of the crank case.

This caused two problems.

First the heating pad was large enough that it raised the contact spot on the inside of the pan to over 300°F in some applications. This caused coking in that area and could even break down the oil. This coke could wash off and plug oil passages or the pickup screen, especially if the system is left on continually.

The other real problem with a single spot heater is that it will vaporize any moisture in the oil, which will rise until it meets the cold camshaft at the top of your Lycoming engine. This will greatly increase the moisture and subsequent rusting of the cam.

I have seen numerous ruined camshafts from engines that used single spot heaters and left them on continuously.

So, what are the best recommendations for pre-heating an aircraft engine?

- Do not drain the oil and just heat it prior to startup unless it is an emergency.

- Pre-heat your engine, not just the oil, to ensure proper clearances.

- Do not leave your electronic heater going all the time if you only have just a heater on the oil pan.

- And always check your oil temperature during cruise flight to ensure that it is in the 180°F range so that you boil off any moisture in the oil during flight.